+8618680445103

+8618680445103

Free Standard Samples can be provided for you to check the quality.

Leave Your Message

Choosing the right container metal for specific applications is crucial in various industries. For instance, aluminum and stainless steel are popular choices, each offering distinct advantages. According to a recent report by the Global Container Metal Association, the global market for container metals is projected to reach $25 billion by 2025. This growth highlights the increased demand for efficient and durable container solutions.

Industry expert Dr. Alice Morgan states, "Selecting the correct container metal can significantly impact performance and cost." This underscores the importance of understanding different metal properties. Aluminum is lightweight and resistant to corrosion, while stainless steel offers durability and strength. Each material has its trade-offs, making it critical to evaluate your specific needs.

Companies often face challenges in balancing costs and functionality when selecting container metals. Many overlook the long-term implications of their choices. Reflecting on these decisions can yield better outcomes. Careful consideration is essential for optimizing performance and sustainability in container solutions.

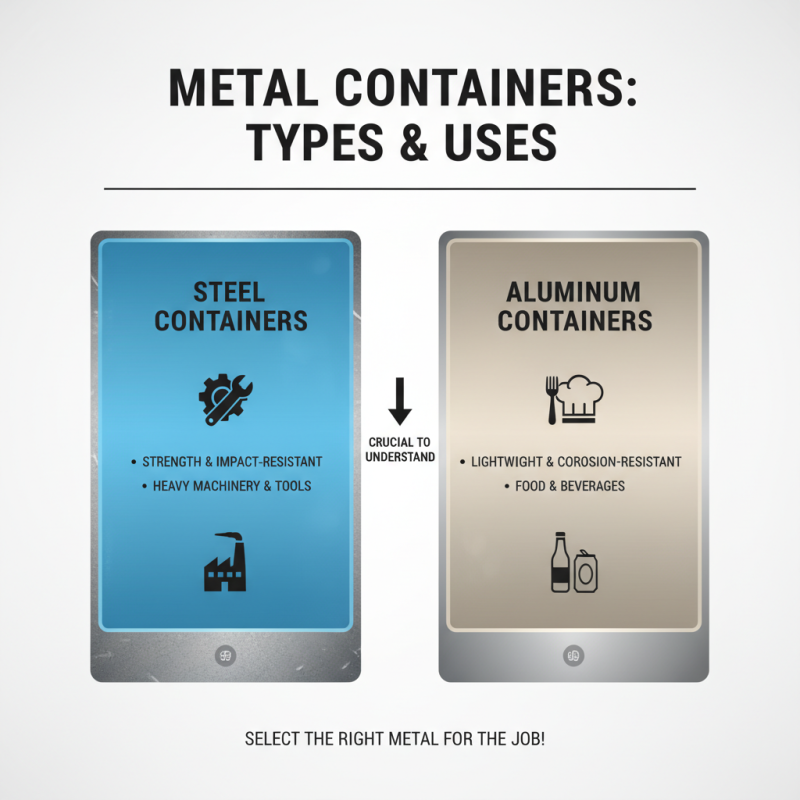

When selecting metal containers, it’s crucial to understand the types available and their common applications. Steel containers are popular for many reasons. They are strong and resistant to impact. This makes them perfect for heavy machinery parts and tools. Plus, they hold up well under harsh conditions. Aluminum containers, on the other hand, are lightweight and corrosion-resistant. They often store food and beverages, making them essential in the culinary industry.

However, choosing the right container involves more than just material. The size and shape matter too. For instance, small metal tins work well for storage of craft supplies. Larger bins may be better for organizing workshop elements. Yet, people often overlook the potential rust or degradation over time, especially in humid environments. It’s vital to consider the environment in which the container will exist.

Reassessing your needs is also necessary. You may need a container that can be sealed tightly. Alternatively, you might prioritize a breathable design for certain materials. The decision often feels overwhelming. Understanding these details can greatly influence the container's functionality and durability.

Choosing the right metal for your containers involves several critical factors. One key consideration is the container's purpose. Will it hold liquids, solids, or hazardous materials? Each requirement can influence your choice. For example, aluminum is lightweight and corrosion-resistant, making it suitable for non-hazardous liquids. However, it might not be the best for heavy solids due to its lower strength.

Another important aspect is the environment where the container will be used. High temperatures or harsh chemicals can affect metal performance. Stainless steel offers good resistance to corrosion and can withstand higher temperatures, but it’s heavier and potentially more expensive. Also, think about how the metal interacts with its contents. For instance, some metals may leach into food, affecting safety and flavor.

Budget constraints are often a reality, so balancing quality with cost is essential. Cheaper options might save money initially but could require replacements. Reflect on the long-term gains versus initial expenses. No single metal fits all needs, and sometimes trial and error may be necessary to find the perfect match.

| Metal Type | Corrosion Resistance | Weight | Cost | Strength | Common Applications |

|---|---|---|---|---|---|

| Aluminum | High | Lightweight | Medium | Moderate | Food and beverage containers |

| Stainless Steel | Very High | Moderate | High | High | Chemical and pharmaceutical containers |

| Carbon Steel | Medium | Heavy | Low | Very High | Industrial containers |

| Copper | Medium | Light | High | Moderate | Electrical containers |

| Titanium | Very High | Light | Very High | Very High | Aerospace and medical containers |

Choosing the right metal for containers requires careful consideration of various factors. Corrosion resistance stands out as a crucial element. Some metals are naturally resistant to rust and degradation, while others succumb quickly under adverse conditions. For example, stainless steel is well-regarded for its durability against corrosion. However, it may not be the most cost-effective choice for all applications.

Tips: Consider the environment where your container will be used. If it's in a humid area or near saltwater, opt for metals with enhanced corrosion resistance. Assessing your specific needs is essential. A cheap metal might save money now but lead to high costs in replacements later.

Another factor to weigh is the potential for coatings. Some metals can be treated to resist corrosion better. It's a good option when you cannot use expensive alloys. Think about the longevity of your containers. A lower upfront cost may entice you, but will it last? Reflect on how often you would need replacements over time. This approach can change your perspective on what metal to choose.

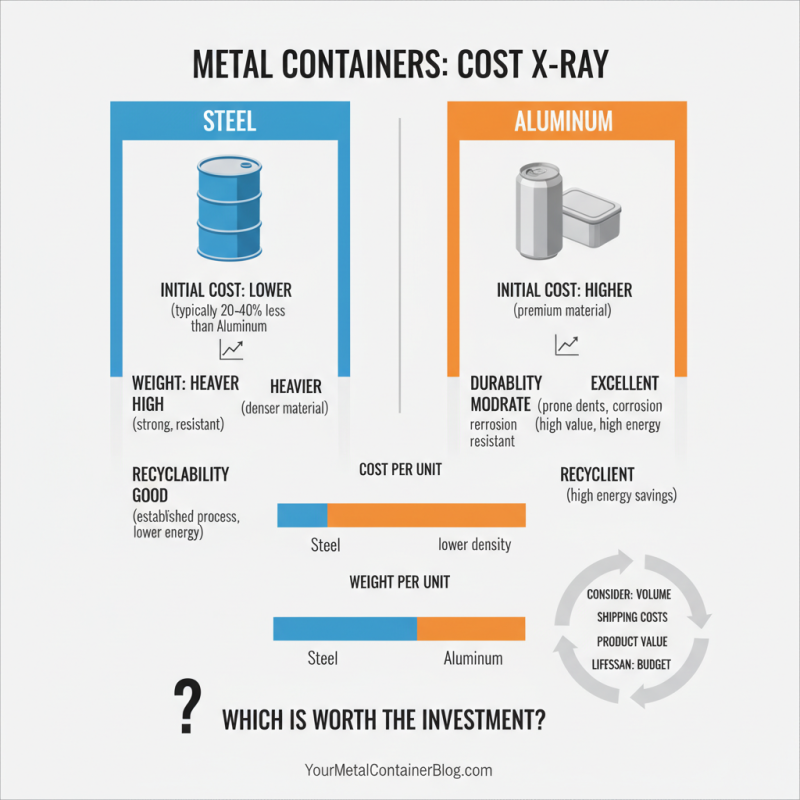

When selecting metal containers, cost analysis is crucial. Different metals come with varying price tags. For instance, steel is often cheaper than aluminum. However, the trade-off includes weight and durability. You might find yourself questioning which metal is truly worth the investment.

Calculate your budget before making a decision. It’s easy to get drawn in by shiny aluminum options. Yet, if your project demands strength, steel may be the better choice. You should also consider long-term use. Will the container withstand harsh conditions? Investigate maintenance costs too. Sometimes, the cheapest option in the beginning leads to higher expenses later on.

Reflect on your specific needs. Are you focusing on transport, storage, or aesthetics? Each purpose may require different container features. Adjust your budget accordingly. Aim for a balance between cost and function. It’s important to weigh these factors carefully. Don't just rely on trends. Assess how each metal container aligns with your goals. Your choices now will impact your future projects.

When considering metal containers, sustainability is a crucial factor. The production of metal can lead to significant environmental impact. Reports show that aluminum production emits around 12 tons of CO2 per ton of metal. Steel fares better but still contributes about 1.8 tons of CO2 for every ton produced. This brings sustainability into question.

Recycling can mitigate some of these impacts. Aluminum, for example, can be recycled indefinitely without losing quality. The recycling process uses 95% less energy than new aluminum production. Steel is also highly recyclable, with about 70% of it being reused in new products. However, recycling rates vary globally. In some regions, only 20% of aluminum containers get recycled properly.

The choice of metal container affects not just usability but also environmental responsibility. Using metal generally leads to less plastic waste. Yet, the high initial production costs and environmental toll require careful consideration. A balance must be struck between efficiency and ecological footprint. This complexity underscores the importance of making informed choices.