+8618680445103

+8618680445103

Free Standard Samples can be provided for you to check the quality.

Leave Your Message

Choosing the right Metal Cans is crucial for various industries, including food and beverage, personal care, and chemicals. A recent report from the Metal Packaging Association indicates that the metal can market is expected to grow by 4.5% annually over the next five years. This underscores the importance of selecting the correct type of can to meet both safety and sustainability standards.

Expert Mike Davis, a renowned analyst in the packaging industry, states, "Choosing the right Metal Cans can significantly impact product longevity and brand reputation." His insights highlight the need for careful consideration. The right can not only preserves the product but also enhances its market appeal.

However, not all decisions are straightforward. Many businesses still overlook critical factors, such as material quality and can size. This can lead to challenges in storage and distribution. It's essential to reflect on past choices and learn from them. Effective selection of Metal Cans requires balancing functionality and cost, a task that isn’t always easy.

When selecting metal cans, understanding the various types is crucial. There are three primary categories: aluminum, steel, and tinplate. Aluminum cans are lightweight and resistant to corrosion. They make excellent choices for beverages. On the contrary, steel cans are stronger and commonly used for food products. According to the Metal Packaging Association, over 90% of U.S. households use steel or aluminum cans.

Tinplate cans, while less common, offer unique benefits. They provide a superior barrier against moisture but may be prone to rust. Consumers need to weigh these factors. Are you picking the right type for your needs? In a recent industry report, it was noted that 33% of consumers still don't know the differences between these materials. This gap shows the need for better education on metal can selection.

Durability is essential, but so is sustainability. Each type of metal can is recyclable, but aluminum has a higher recovery rate—about 75% compared to steel. Many consumers are unaware of this truth. Reflecting on your choices is vital. Are you prioritizing functionality or environmental impact?

Choosing the right metal can is crucial. The material and thickness of the can greatly influence preservation and safety. Metals like aluminum and tin are popular. Each has its own benefits and drawbacks. Aluminum cans are lightweight and resist corrosion. Tin offers better preservation for certain products, yet can be prone to rust.

Thickness is another vital consideration. Thicker cans provide better protection against physical damage. However, they may be heavier and costlier. A balance needs to be struck. For example, if you’re storing perishable items, a thicker can might be more efficient. But if you’re looking for portability, think thinner.

Reflect on your needs and the specific conditions your cans will face. Look into storing temperature and humidity. These factors can change how well a can preserves its contents. Even the best materials can have flaws. Investing in quality matters, but so does understanding your unique requirements.

| Can Type | Material | Thickness (mm) | Preservation Benefits | Safety Considerations |

|---|---|---|---|---|

| Standard Food Can | Tinplate | 0.30 | Excellent barrier to light and oxygen | Non-toxic material, BPA lining concerns |

| Aerosol Can | Aluminum | 0.25 | Effectively preserves the contents under pressure | Pressure safety standards must be met |

| Paint Can | Steel | 0.40 | Prevents solvent evaporation | Ensure proper sealing to avoid spills |

| Beverage Can | Aluminum | 0.24 | Good protection against UV light | Internal coatings to prevent contamination |

| Specialty Can | Tinplate with PVC lining | 0.35 | Enhanced corrosion resistance | Check for heat resistance |

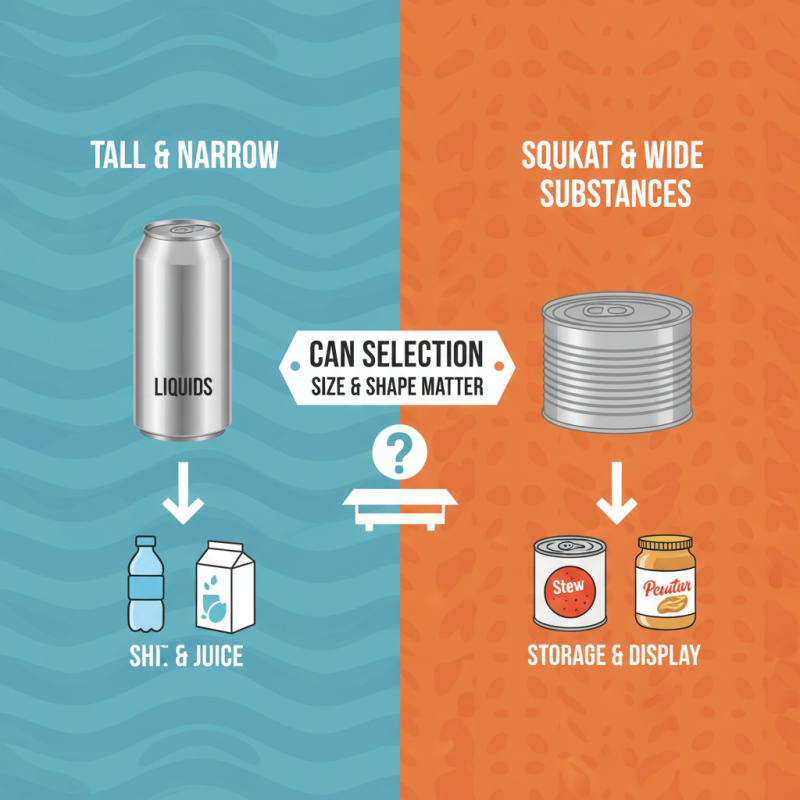

When selecting metal cans, size and shape play crucial roles. It's essential to consider the product you intend to package. A tall, narrow can may work well for liquids. However, a squat can might be better for thicker substances. Think about how the shape affects storage and display. Some cans fit well on shelves, while others struggle for space.

Choosing the right size is equally important. Assess the volume of your product. Oversized cans can lead to wasted space. Conversely, too-small cans might not hold enough. Consider potential future needs. You might need to adjust your can sizes as your product line expands. This reflection can save you time and effort down the line.

Sometimes, it helps to visualize the can in action. Picture product filling and pouring. How will the shape influence user experience? A can that looks good on a shelf might not function well for pouring. Test different designs if possible. Engaging with prototypes can lead to valuable insights. Making the wrong choice now could lead to higher costs later.

When choosing metal cans, environmental impact should be a priority. Metal cans are highly recyclable. However, not all are created equal. It's crucial to assess the materials used in production. Aluminum and steel have different recycling rates. Some regions may lack proper recycling facilities. This impacts the sustainability of the product.

The journey of a metal can doesn't end with disposal. It’s essential to consider the entire lifecycle. Metal cans can take up to 200 years to decompose if not recycled. And let’s not forget the energy used in manufacturing. This often exceeds what is saved through recycling. Reflecting on this, we can question our choices. Are we doing enough to support sustainable solutions?

Proper recycling should be emphasized. Many consumers are unsure about how to recycle cans properly. Local guidelines can be convoluted. Understanding this can help bridge the knowledge gap. The responsibility lies with both manufacturers and consumers. Together, we can promote a greener future, one can at a time.

When selecting metal cans, cost-effectiveness plays a significant role. Prices can vary widely based on the type and size of the can. Bulk purchasing often leads to discounts. Yet, smaller orders might seem less effective, but they can meet specific needs without excess. Understanding these patterns helps make smarter choices.

Consider also the materials used in production. Different metal compositions may affect durability and price. Cheaper options might lead to higher costs later. Evaluate the long-term value. You might save upfront, but a lower quality can result in product damage. This trade-off deserves thorough consideration.

Market trends fluctuate, impacting metal can prices. Stay updated on industry movements. Prices may spike during demand surges. Seasonal trends can also play a role. Being informed can help you act wisely. Yet, relying solely on price can lead to pitfalls. Quality should never be compromised for cost. Balancing price and value is vital for successful decisions.