+8618680445103

+8618680445103 Global Metal Cans Market to Reach $406.85 Billion by 2030

Food and beverage Metal Cans are containers made of metal, typically aluminum or steel, designed to package and preserve various food and beverage products. Such as,aluminium containers for food health care product. These cans provide a protective barrier against light, air, and moisture, helping to extend the shelf life of the contents and maintain product freshness. For example, aluminum containers(Custom 100ml Recycled Food Grade Tin Containers) are widely used for food, health care products, and other industry application.

Metal cans are commonly used to package a variety of beverages, including soda, juice and alcoholic beverages, as well as a variety of food products such as fruits, vegetables, soups and ready-to-eat foods. They are favored for their durability, impact resistance, and ability to be hermetically sealed to prevent contamination.

In addition, metal cans are often chosen for their recyclability, making them an environmentally friendly packaging option. The versatility and efficiency of food and beverage metal cans contribute to their widespread use in the packaging industry.

In-depth analysis of food and beverage metal cans market drivers

The food and beverage metal cans market is influenced by a number of factors, which are related to various aspects such as consumer trends, environmental requirements, manufacturing technologies, innovations, and others. Following is an in-depth analysis of the drivers of the food and beverage metal cans market:

Recyclability and Environmental Trends

Recyclability of metal cans: metal cans can be reused through recycling, in line with modern society's need for sustainability and environmental protection, which is an important factor driving the growth of the metal cans market.

Reduced Plastic Use: There is a growing concern globally to reduce the use of plastics, and metal cans are favored by consumers and manufacturers as an alternative packaging material.

Product Innovation and Diversity

New Metal Packaging Technologies: Manufacturers continue to push the boundaries and develop new metal packaging technologies to improve the durability, lightweighting, and production efficiency of metal cans to meet diversified market demands.

Multi-layer structure and functional design: Innovative multi-layer structure design can improve the freshness and corrosion resistance of metal cans, adapting to different types of food and beverages.

Consumer Preferences and Brand Image

High-end packaging needs: metal cans are often seen as high-end packaging that can enhance a product's brand image and fulfill consumer demand for quality and unique packaging.

Portability and Convenience: Metal cans are lightweight and easy to carry, which is suitable for the fast pace of modern life and meets consumers' preference for convenient and easy-to-use packaging.Freshness characteristics of metal cans: metal cans can effectively isolate the outside air and light, which helps to maintain the freshness and quality of food and beverages, to meet consumer requirements for food safety.

Anti-corrosion properties: metal cans have better anti-corrosion properties, which can prevent the contamination of food by external substances and extend the shelf life of food.

Economic factors and price competition

Relatively low production cost: the production cost of metal cans is relatively low, which makes the metal cans have a competitive enterprise advantage in price to meet the mass market demand.

Economical scale of mass production: Large-scale mass production of metal cans can further reduce production costs and improve market competitiveness.

Globalization and International Trade

Market Expansion of International Brands: International brands are increasingly focusing on global market promotion, and metal cans, as a universal packaging form, help standardize product packaging.

Supply Chain Integration of Multinational Companies: Multinational food and beverage companies often tend to integrate their supply chains, and the use of metal cans can realize a more integrated packaging process.

Emerging Markets and Consumption Growth

Demand for convenience foods in emerging markets: With the rise of the middle class in emerging markets, the demand for convenient, high-quality packaging has increased, and metal cans are expected to gain more opportunities in these markets.

Expansion of the beverage market: metal cans have a wider application in the beverage market, and as the beverage market expands, the metal can market is expected to follow the growth.

Detailed Study on Future Technology Development Trends of Food and Beverage Metal Cans

The future technology trends of food and beverage metal cans may involve material innovation, intelligent packaging, sustainable design and many other aspects. The following is an in-depth analysis of the future technology development trends of food and beverage metal cans:

Intelligent Packaging Technology

RFID and Sensor Technology: Future metal cans may integrate RFID (Radio Frequency Identification) and sensor technology to realize real-time monitoring and tracking of products, and improve visibility and traceability of the supply chain.

Smart labels: The use of smart labels will enable consumers to access information about product origin, quality and safety, enhancing consumer experience and product trust.

Lightweight Materials and Design Innovations

High-strength materials: Future metal cans may use lighter, but still high-strength metal alloys to reduce the weight of packaging and lower transportation costs.

Structural design innovation: For different products and needs, the structural design of metal cans may be further innovated to improve the functionality and adaptability of packaging.

Sustainability and Environmental Design

Biodegradable Coating: Utilizing biodegradable coatings, metal cans can better comply with the requirements of sustainability and environmental protection, and reduce the impact of packaging on the environment.

Recycling design: Metal cans can be designed to be more easily recovered and recycled, minimizing waste and resource wastage.

Efficient Production Processes

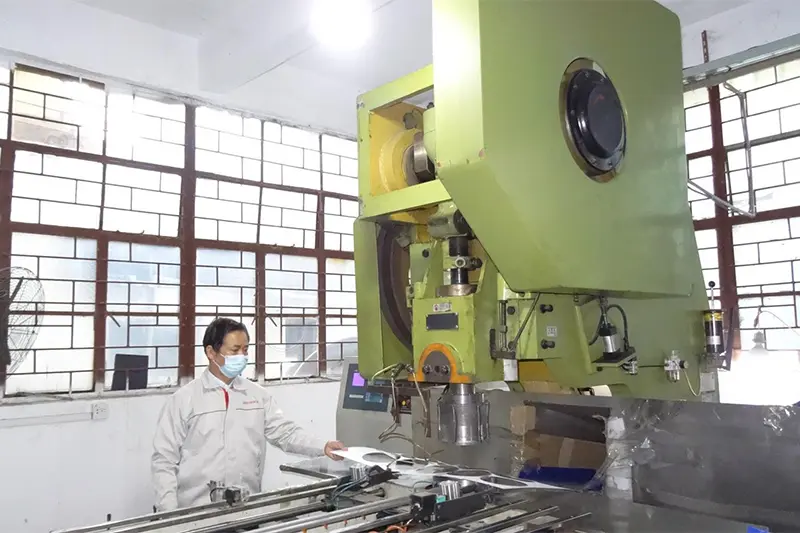

3D Printing Technology: The application of 3D printing technology can speed up the production process of metal cans and increase production efficiency, while allowing for more flexible design and personalization.

Automated production line: Automation and intelligent technologies are introduced to optimize the production process, reduce labor costs, and improve the efficiency and stability of the production line.

Packaging and design personalization

Digital Printing Technology: The use of digital printing technology allows for the personalization of metal cans to meet market demand for individualized products and brands.

Customizable design: Consumer demand for personalization and special design is gradually increasing, and in the future metal cans may pay more attention to customizable design to meet the requirements of different brands and products.

Advanced anti-corrosion technology

Nano-coating technology: The introduction of nano-coating technology can improve the resistance of metal cans to corrosion and oxidation, and extend the shelf life of products.

Gas protection technology: The use of gas protection technology can effectively reduce the oxygen content of the air inside the package, thus slowing down the oxidation process of food and beverages.

Internetization and digital integration

Internet of Things (IoT) applications: The introduction of IoT technology enables metal cans to be connected to the Internet, thereby improving production efficiency, enabling smart packaging and real-time monitoring.

Digital Supply Chain: Integrate the supply chain through digital technology to achieve efficient collaboration among production, warehousing and logistics, and improve the visibility and responsiveness of the supply chain.

In-Depth Analysis of Restraints in the Food and Beverage Metal Cans Market

The Food and Beverage Metal Cans market may face a number of restraints during its development, which are related to various aspects such as technology, economics, environmental protection, consumer behavior, and others. Following is an in-depth analysis of the restraining factors for the food and beverage metal cans market:

Cost Factors

Fluctuating raw material prices: the manufacturing of food and beverage metal cans relies on metallic raw materials, and fluctuating raw material prices may affect production costs, posing a challenge to the industry's profitability.

Manufacturing and processing costs: metal cans are relatively expensive to produce and process, especially with some emerging technologies and environmental requirements, which may affect the price competitiveness of metal cans in the market.

Environmental Pressure

Competition from plastic alternatives: As environmental awareness increases, plastic alternatives are emerging in the packaging industry, and some consumers and brands may prefer to use biodegradable materials, creating competition for metal cans.

Recovery and recycling pressure: Although metal cans are recyclable, recovery rates and recycling efficiency remain a challenge, especially if the recycling infrastructure is not robust enough in some regions.

Innovation pressure and market saturation

Packaging material innovation: The food and beverage industry has been pursuing new packaging materials, such as biodegradable materials, paper-based packaging, etc. These innovations may pose competitive pressure on the metal can market.

Market saturation: In some developed markets, the food and beverage metal cans market may already be relatively saturated, and further expansion of market share becomes more difficult.

Weight and Transportation Issues

Relative weight: The relative weight of metal cans compared to lightweight packaging, such as plastic bottles, can increase transportation costs, especially over long distances.

Carbon Footprint Issues: Transporting metal cans over long distances may result in a higher carbon footprint, and the focus of some companies and consumers on carbon neutrality and low carbon footprints may influence the choice of metal cans.

Supply Chain and Trade Uncertainty

Global Supply Chain Issues: Uncertainty in the global supply chain, including raw material sourcing and disruptions in the production chain, may cause some degree of distress in the production and supply of metal cans.

International Trade Friction: Tensions in international trade relations may cause a degree of trade uncertainty in the import of raw materials and export of finished products for metal cans.

Global Food and Beverage Metal Cans Market Size Current Analysis and Future Forecasts

According to the research statistics of DIResaerch, the global food and beverage metal cans market size shows a steady expansion trend, the global food and beverage metal cans market size was 320.7 billion dollars in 2023, and it is expected to reach 406.85 billion dollars in 2030, with a compound annual growth rate (CAGR) of 3.02% during 2023-2030. The North American market accounted for 27% of the total, followed by Europe with 22%.

Conclusion

The global metal cans market is poised to grow significantly, reaching $406.85 billion by 2030, driven by increasing demand in food, beverage, and industrial packaging sectors, alongside a focus on sustainability and recyclability.