+86-18998410690

+86-18998410690 Why milk is not packaged in aluminum cans?

In the market, milk is usually packaged in cartons (e.g. Tetra Pak), plastic bottles and glass bottles, while aluminum cans are less commonly used. This phenomenon is not accidental, but is determined by a combination of factors, including chemical stability, preservation conditions, production costs, supply chain suitability and market acceptance.

Chemical stability issues

The acidity of milk and proteins may affect the stability of aluminum can. The pH value of milk is about 6.5-6.8, which is weakly acidic, in which lactic acid and other components may have a chemical reaction with aluminum, leading to the dissolution of aluminum ions: acidic effect: aluminum may slowly dissolve in acidic environments, leading to the entry of aluminum ions into the milk, which may not only affect the taste, but also bring health risks, such as neurotoxicity (long-term intake of excessive aluminum is associated with Alzheimer's disease and other diseases).

Aluminum cans are not suitable for milk storage conditions

Aluminum cans are not suitable for refrigerated storage Thermal conductivity: Aluminum's thermal conductivity is much higher than that of plastic and cartons, and under refrigerated conditions, the surface of aluminum cans is prone to condensation, which affects storage and transportation. Easily deformed, affecting sealing: aluminum cans may deform due to gas expansion or contraction in environments with large temperature variations, affecting the sealing effect and leading to an increased risk of contamination.

Production and cost factors

Aluminum packaging costs more milk belongs to the bulk of consumer goods, in the global low-cost, high circulation as the main mode of operation, and aluminum cans manufacturing and packaging costs are significantly higher: high production costs: aluminum cans manufacturing and packaging process is complex, especially the liquid sealing technology requires stringent requirements, and cartons and plastic bottles of the process is more mature, the cost is relatively low. Transportation and storage costs increase: aluminum cans compared to collapsible cartons, occupying more space,

Consumer acceptance and market preference

Consumer habits are different Currently, milk packaging in the market is mainly based on cartons, plastic bottles and glass bottles, which has formed the inherent cognition of consumers for a long time. Aluminum cans of milk have a lower degree of cognition, and it is difficult to promote the market. Aluminum cans do not meet the brand image of milk aluminum cans are mainly used for carbonated beverages, consumers tend to associate it with soda, beer, energy drinks, and milk emphasizes “healthy, natural, fresh”, and aluminum cans do not match the bubble sense of association.

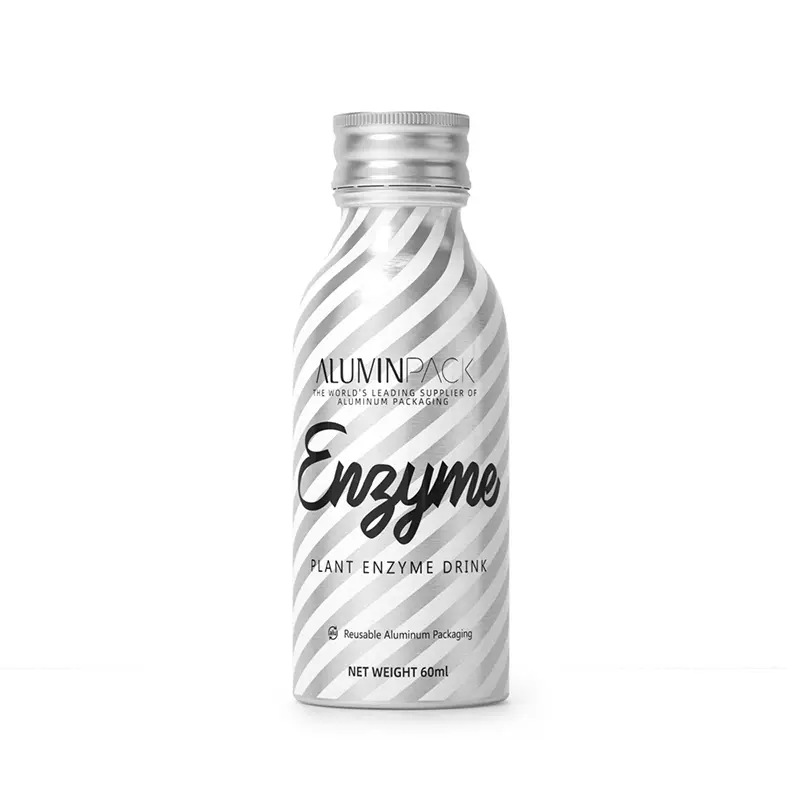

Exception: dairy products in aluminum cans

Although ordinary milk is almost never packaged in aluminum cans, such as 500ml aluminum tin for coffee beans product, the following types of specific dairy products will still use aluminum cans: high-end coffee milk, flavored milk, milkshakes: some brands use aluminum cans, mainly used to enhance the texture of the product, and with the help of aluminum cans with a high resistance to light to extend the shelf life. High-fat dairy products such as cream, condensed milk: these products are fundamentally different from ordinary milk, usually thicker and more stable, and some brands choose aluminum cans or metal cans for packaging.